Why We Don’t Use the ScanNCut Fabric Support Sheet (& What We Use Instead)

If you cut fabric with the ScanNCut, then you are probably already aware of the Hight Tack Fabric Support Sheet. For those that aren’t aware, it’s basically a sheet of sticky plastic that is applied onto a Standard Mat in order to make the mat stickier so that fabric can adhere to it better.

Fabric needs to be on a nice sticky surface in order for it to cut well with the ScanNCut and the High Tack Support Sheet was made for that purpose.

It comes in a roll and you simply peel off the backing and apply it to a Standard Mat. You place your fabric on it and cut away.

Sounds great right?

Well yes and no. It does keep the fabric nicely secured to the mat, but that’s about as good as it gets…at least in my opinion.

So why don’t I like it?

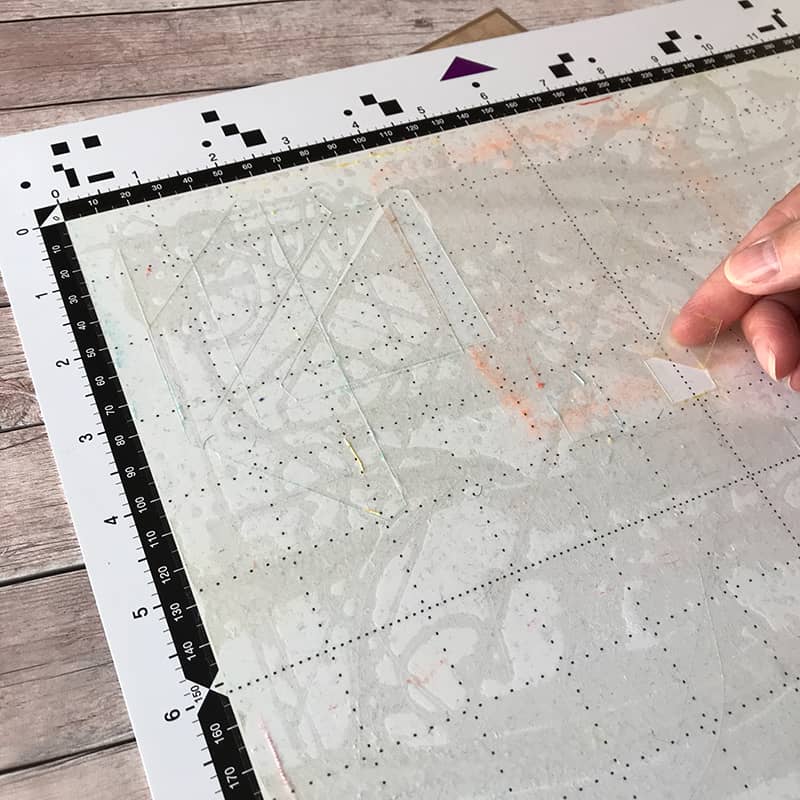

1. The sheets can be a little tricky to apply since they come in rolls, and this can create air bubbles or wrinkles when applied to the mat. Bubbles and wrinkles can be difficult to remove. And although it’s not a big deal to have some small air bubbles in the fabric sheet, as you can work with that, I’d rather they weren’t there. So be prepared for a bit of lifting and repositioning the sheet to remove the air bubbles.

2. Once you start cutting with your fabric, you will find that cuts are created in the sheet. The more you cut, the more the blade slices through the fabric sheet and pretty quickly there are shards of plastic created that easily come off and can stick to the back of your fabric. And you are essentially left with gaps in the support sheet.

3. Once you have applied the Fabric Support Sheet, you are going to have a hell of a time if you want to remove it because all of those shards of plastic have to be picked off one at a time. I personally don’t have the patience and that means throwing out the standard mat because it is no longer usable, I am not willing to do that.

4. They need to be replaced often, so it can be expensive to continually buy new sheets.

5. Since the mat is so super sticky, it can be difficult to clean. You can pick off the threads and then use a wet wipe but when you do this, those little shards I was talking about come off with the wet wipe. So you have to be real gentle when you clean which means it doesn’t clean up very well.

So what do we use instead?

There are two things that we use instead of the High Tack Fabric Support Sheet depending on which version of the machine we are using:

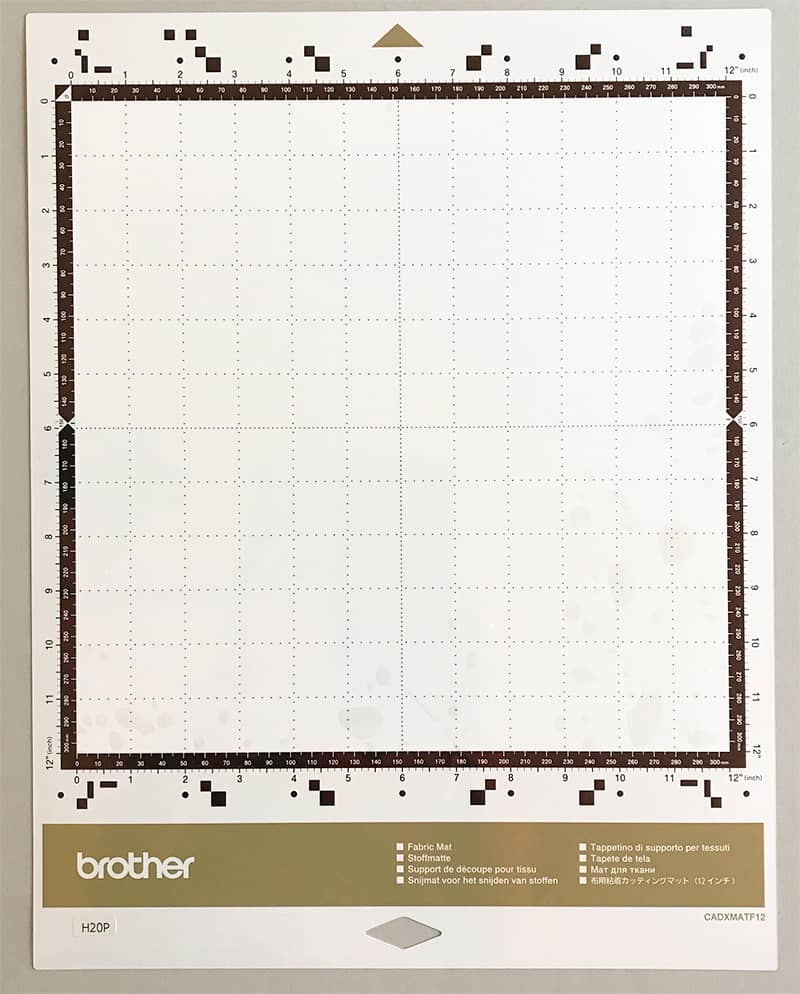

1. Fabric Mat

For the DX machines, we now use the Fabric Mat (but we also use the second option below when this mat has lost its stickiness).

The Fabric Mat is relatively new and is only available (at time of writing this post) for DX machines. Since it is sticky enough on its own, it doesn’t need the Fabric Support Sheet.

2. Temporary Fabric Adhesive Spray

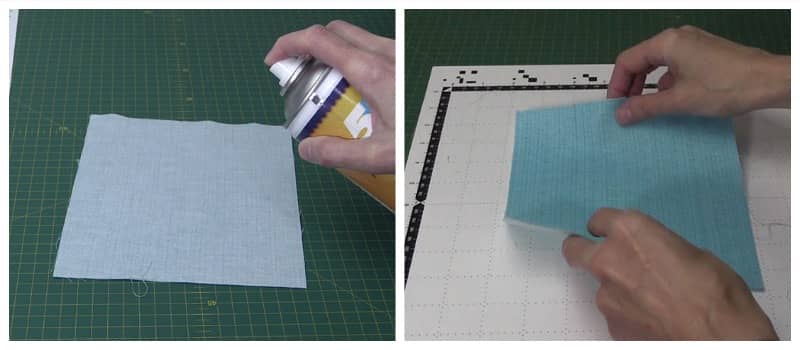

For the CM machines (which don’t have a fabric mat option) we use a temporary fabric adhesive spray. However, we also use fabric adhesive spray for DX machine mats when they lose their stickiness.

Fabric adhesive spray is one of the best things you can own if you are cutting fabric with your ScanNCut. It holds the fabric on the mat really well.

Just lightly spray your fabric, place the fabric on the mat and smooth it down nicely.

Just remember to always spray the fabric and not the mat.

My adhesive spray of choice is 505 spray which you can buy from Amazon here (affiliate link) but I should think any adhesive spray will work as long as it specifically states that it works with fabric. You don’t want a spray that is going to gum up your sewing machine so go with a good one.